bull nose end mill vs flat end mill

Bull-nose end mills are often used to mill molds plastic injection molds die cast molds etc 2. Youd still have basically zero SFM at the center of the ball end mill and a much less stiff cutter.

General Tool Geometry And Surfaces Of The Various End Mills A General Download Scientific Diagram

Im looking for a bull nose end mill.

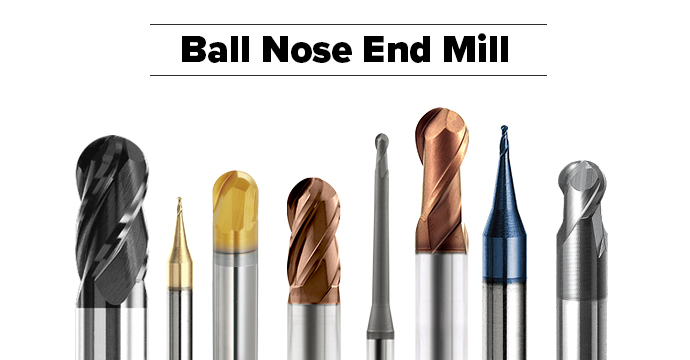

. Ball Nose End Mill. That is an endmill with a round chamfer on the corner. These radius end mills are single ended tools used for making corner radii at the bottom of a.

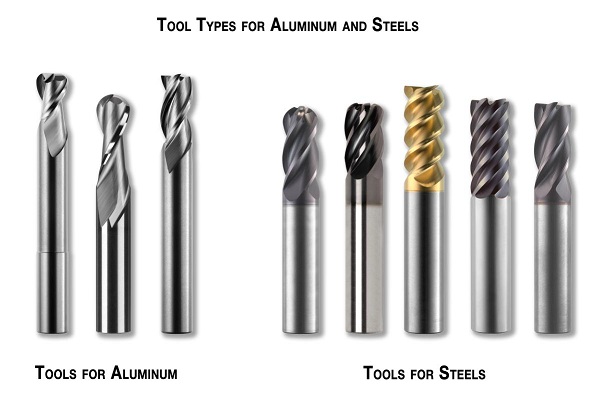

Flat end mill is the end mill with flatsquare end. The words end mill are generally used to refer to flat bottomed cutters but also include rounded cutters referred to as ball nosed and radiused cutters referred to as bull nose or torus. End mills come in a variety of shapes.

For this reason a double-ended mill is less expensive than two single-ended mills. This creates a constant. I found one with a 062.

The most common are flat end mills. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. These have a flat bottom but rounded corners so you can have a filleted inner corner while also.

End mills - with so many to choose from which one is right for your next CNC project. A fishtail end mill has a flat end so it will produce a flat surface with a clean edge on thin materials. Made of cobalt steel these end mills have good heat and wear resistance so they can run at high speeds in hard material.

The compression end mill creates a smooth surface on top and bottom which is perfect for pre-laminated woods. This type of tooling features flutes with no flat bottom rounded off at the end creating a ball. You can also use it to make pockets with flat bottoms.

The ball has a radius with its center point at the center of the end mill so the radius is always 12 of the. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of. A ball end mill is constructed of a round cutting edge and used in the machining.

There are a few ball end mill uses the big one being. Ball nose end mills also known as full radius end mills or ball mills are cutting tools where the nose radius is equal to half of the diameter of the tool. Bull-nose End Mill.

I dont have much experience with this but it seems like if you have the room to. Sterling Edges backdraft bullnose inserts are standard for profiling on draft walls requiring chip clearance. 164 2-flute flat end mill.

Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters. Bull-nose end mills. Endmills are available in a wide.

Bull-nose end mills are often called corner radius end mills and are a combination of fishtail and ball-nose. A ball end mill is not the same as a corner radiusbull nose end mill. What is a ball end mill used for.

Bull nose inserts are used in finishing when milling flats and sides. The radius of its round corner is smaller than the cutting radius. 1100 2-flute flat end mil.

The flat end mill is widely used in groove processing side processing and step surface processing. End mills in different number of flutes. Bull-Nose Corner Radius End Mill.

Also called corner radius end mills this type of cutter is a combination of fishtail and ball-nose also a flat bottom but with rounded corners. Often used for slotting and pocketing cuts in mold and die making. There are also bull nose end mills these have radiused corners that are smaller than the radius of the cutter.

A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. For high production facilities. Machinists can effectively purchase twice the tool for well under twice the cost.

It is a general end type for rough millingmore economic compared with ball end mill and corner radius end mill but it is. You can see bull-nose end mills as a transition between flat and ball-nose ones. The flat end mill is widely used in groove processing side processing and step surface processing.

Check out our informative End Mill Comparison Guide and learn which to. A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. I dont have much experience with this but it seems like if you have the room to run it a bull nose EM has got to be a better way to go for stiffness lower spindle RPM for a given SFM.

It needs to be 38 diameter with a 18 radius on the bull nose. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Fishtail End Mills.

Ball Nose Milling Without a Tilt Angle.

End Mill An Overview Sciencedirect Topics

Xcan 2 Flute Ball Nose End Mill 4 6mm Shank Cnc Router Bit Carbide End Mill Spiral Milling Cutter Milling Cutter Aliexpress

What S The Difference Between Flat Ball Angle Radius End Mill

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Common Types Of End Mills 3 1 Voxel Based Mrr Expression Of The Download Scientific Diagram

Hanzel 5 Things Should Know How To Selecting End Mill

End Mills The Essential Beginners Guide

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Hanzel 5 Things Should Know How To Selecting End Mill

What S The Difference Between Flat Ball Angle Radius End Mill

The Best Bull End Mill To Find The Finest Quality Bull End Mill From A Manufacturer Supplier Wholesaler Distributor And Factory

China Carbide End Mill Tools 4 Flutes Flat End Milling Cutter China Milling Cutter End Mill

Three Common Shapes Of End Mill Tool Engin Altintas 200112 Download Scientific Diagram